Precision Printing for Powerful Results

Print Mastery

With over 50 years of experience as a Master Printer, LCP’s stunningly beautiful work, superior quality controls, and customer-first culture have no equal in our industry.

Printing today is much more than putting ink on a substrate; it is the delicate balance of art and science. We keep everything we do under one roof to guarantee quality, efficiency, and maximize our customers’ return on investment.

Strategic Impact

Having worked with a vast number of industries and organizations during the past five decades, we also have an unmatched expertise in creating innovative, attention-grabbing marketing strategies, tailored to each customer’s specific audiences.

LCP is proud to be GRACol G7 Master Printer certified and has received many awards for our work.

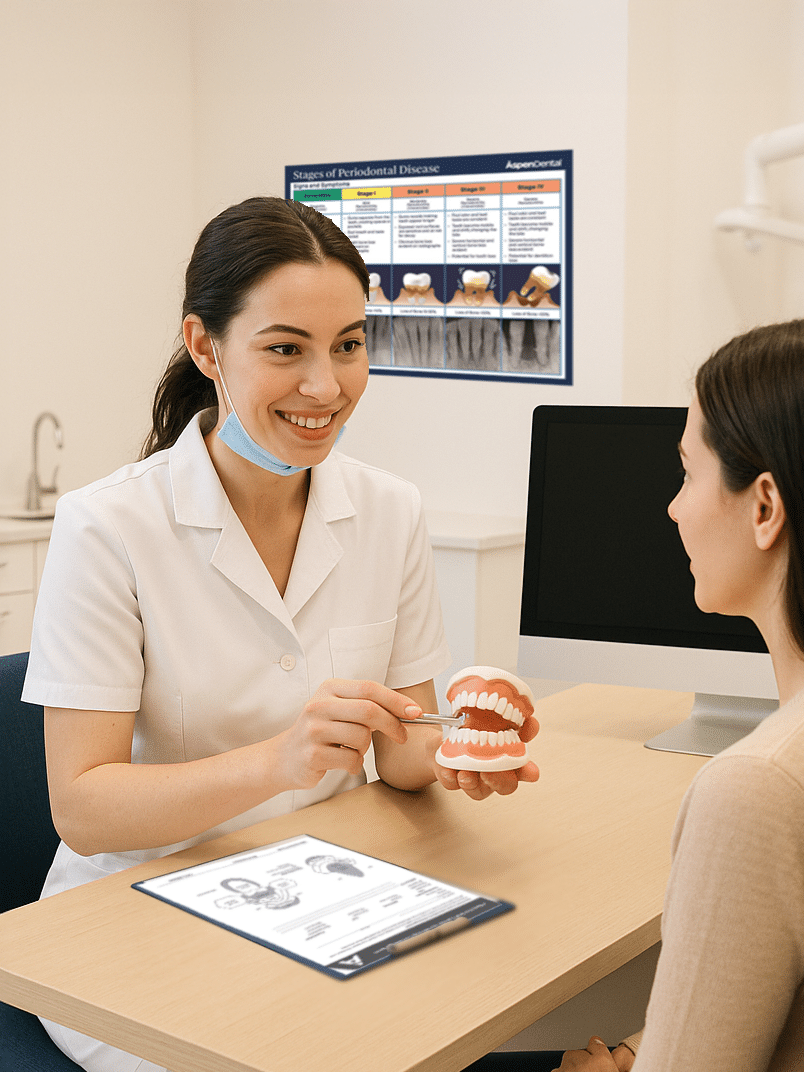

Your World in Print

LCP provides a wide variety of printing services that help our customers solidify their brands and stand out from the noise of today’s business landscape.

Conventional Offset Printing

Using only Heidelberg 4, 6, or 8 color machines, with ink formulated from our own lab, we harness the best of today’s printing technology, special effects, and color science to produce superior results. Our highly skilled press operators are the best at what they do.

UV Offset Printing Services

UV offset printing offers brilliant, lifelike color, and special effects with a variety of substrate options. Using two fully interdecked, Heidelberg 8 color presses, and ink from LCP’s own labs, our dedicated UV team has extensive experience in this form of printing.

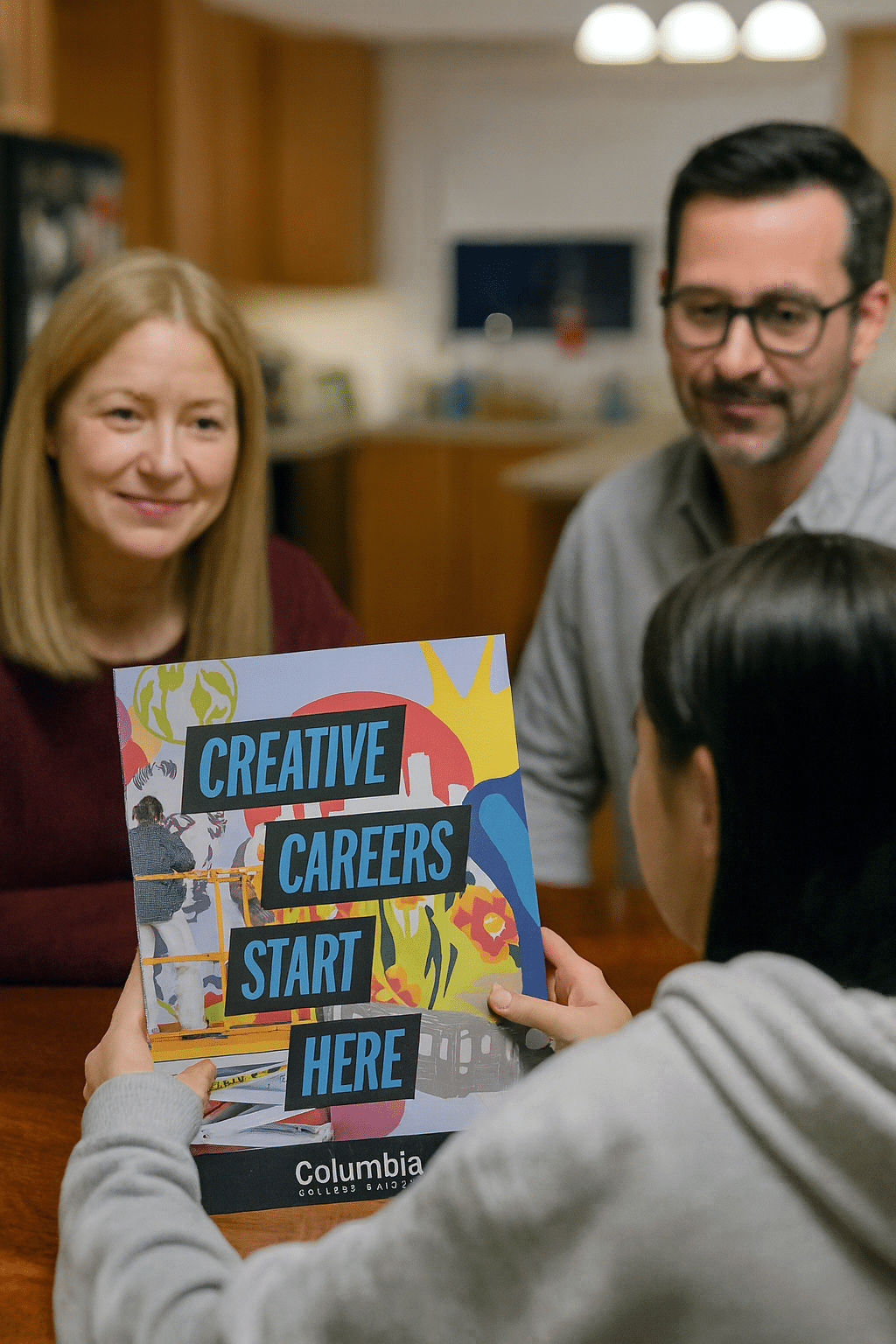

Digital Printing Solutions

In the world of digital printing, the printing itself is only the beginning. With precision color matching, and the use of data to target specific audiences, digital printing is a powerful tool.